It’s the material which can withstand all kinds of acid corrosion of oxalic acid, sulfuric acid - ferric sulfate, nitric acid, nitric acid - hydrofluoric acid, sulfuric acid - copper sulphate, phosphoric acid, formic acid, acetic acid. It is widely used in chemical, food, pharmaceutical, paper, oil, atomic energy and other industries, as well as architecture, kitchen utensils, cutlery, vehicles, household appliances and all kinds of parts.

In order to ensure the mechanical properties of yield strength, tensile strength, elongation and hardness of various types of stainless steel plate, it must be after annealing, solution treatment, aging treatment and other heat treatments before delivery.

The corrosion resistance of stainless steel depends on the alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and internal organizational structure, chromium plays a major role. Chromium has a high chemical stability, can form a passive film on the surface of steel, the passive film can isolate the metal from the outside world and protect the steel plate from oxidation, and to increase the corrosion resistance of steel plate. After the destruction of the passive film, corrosion resistance will be decreased.

Classification:

-

According to the thickness

- steel sheet

- medium plate

- heavy plate

- extra thick plate

- According to production method

- Hot rolled steel plate

- Cold rolled steel plate

- According to surface characteristics

Surface Treatment Code Manufacturing method summary Application No.1 annealing and pickling treatment after hot rolling.

cold rolling materials, industrial tanks, and industrial chemical devices.

No.3 polished with 100~120 mesh abrasive.

building exterior and interior, home appliances, and kitchen installations.

No.4 polished with 150~180 mesh abrasive. Compared to No.3, this product has a finer abrasion condition. Its surface is an attractive silvery-white

bathtubs, building exterior and interior, and food industry.

No.2B No. 2B is the type that had skin-pass (temper-rolling) performed on No.2D. It has better gloss and surface flatness compared to No.2D. It is the standard surface class with improved mechanical properties

It is applicable for almost all uses.

No.2D No. 2D is a non-glossy cold-rolled product that has undergone annealing and pickling treatment after cold rolling

Used in petrochemical plants, automobile parts, building materials, and pipes.

BA BA is bright and highly reflective surface produced by bright annealing after cold rolling.

used in home appliances, small-sized mirrors, kitchenware, building materials and others that require reflective properties.

HL HL is a type of surface with continuous striped pattern acquired by polishing the surface with No.4 abrasive.

It is widely used for building exterior and interior, sashes and doors.

Dull Dull surface is matte finish produced by reducing gloss from No.2B and creating roughness on the surface.

building exterior and interior, roofing and elevators that require reduced light reflection.

NO.7 polished with 600 mesh abrasive.

Art, decoration

NO.8 Polished with mirror polishing wheel

Reflective mirror, decoration

NO.240 Performed on NO.2D and NO.2B material, polished with 240 mesh abrasive

kitchen installations

NO.320 Performed on NO.2D and NO.2B material, polished with 320 mesh abrasive

kitchen installations

NO.400 Performed on NO.2B material, polished with 400 mesh abrasive

building materials, kitchen installations

- According to usages

- bridge plate

- boiler plate

- ship building steel plate

- armour plate

- autobody sheet

- roofing sheet

- structural steel

- electrical steel

- spring steel

- solar panels

- According to the steel group

- Austenitc

- Austenitic-Ferritic

- Ferritic

- Martensitic

Commonly used stainless steel grades table at home and abroad

No |

China GB |

Japan |

American |

Korea |

European |

India IS |

Australia AS |

Tai Wan CNS |

||

Old Grades |

New Grades |

ASTM |

UNS |

|||||||

| Austenitic stainless steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | 202 | |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | ~02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic stainless steel | ||||||||||

| 23 | 0Cr26Ni5Mo2 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | - | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | - | 329J3L | 329J3L |

| Ferritic stainless steel | ||||||||||

| 25 | 0Crl3Al | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | - | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | - | - | STS410L | - | - | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 |

| 30 | - | 022Cr18NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | - | 444 | 444 |

| Martensitic stainless steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | - | - | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | - | - | STS420J2 | 1.4028 | 30 Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | - | - | 440A | 440A |

Dimensions

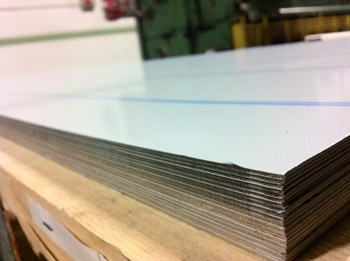

The Stainless Steel can be delivered as follow:

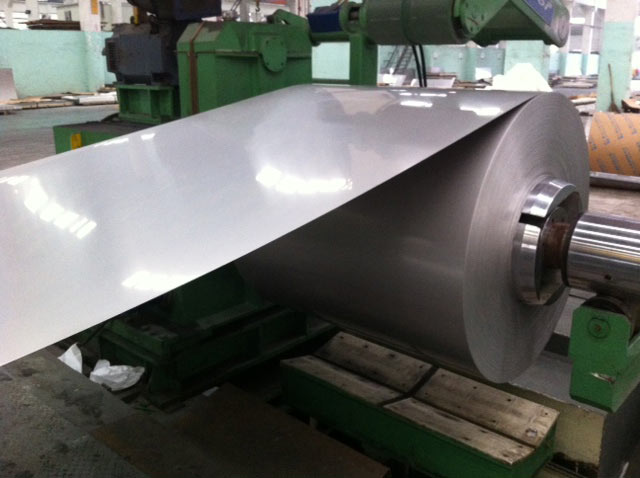

- Coil: width from 1000mm to 1500mm; thickness from 0.3mm to 6mm.

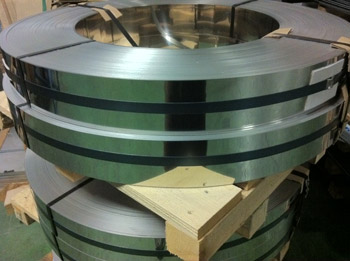

- Strip: width from 20mm to 999mm; thickness from 0.3mm to 3mm.

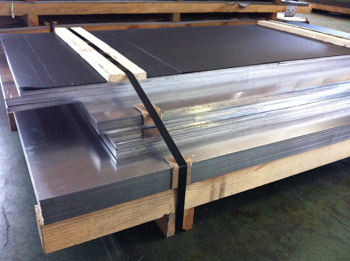

- Sheet: width 1000mm, 1220mm, 1250mm, 1500mm and 2000mm x length 2000mm, 2440mm, 2500mm and 3000 mm; thickness from 0,3 to 3mm.

- Plate: width 1500mm and 2000 mm x length 2000mm to 12000 mm; thickness from 4mm to 100 mm.